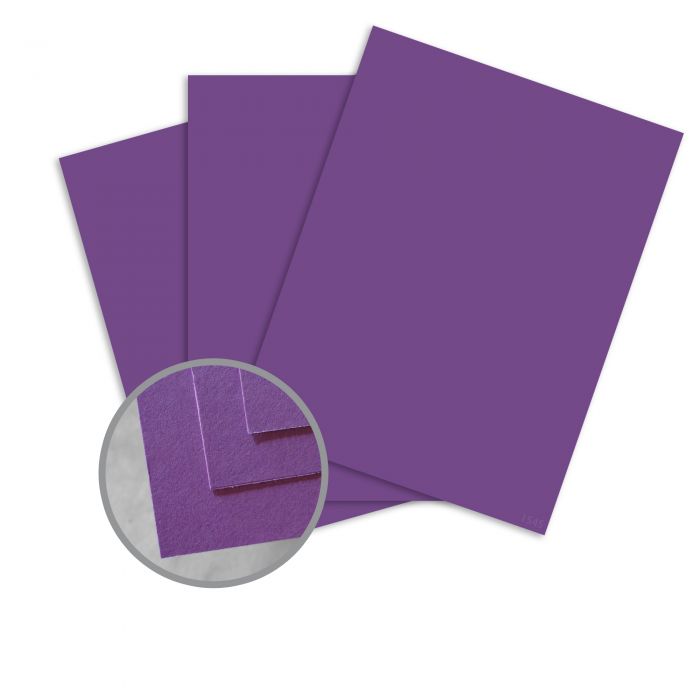

BriteHue Violet Paper - 8 1/2 x 11 in 60 lb Text Semi-Vellum 30% Recycled 500 per Ream

by Mohawk Fine Papers

see more detailsAdd Paper Services

Paper services are available when viewing this page on a desktop computer

Select Paper Services

Buy in Bulk and Save

- 10 Reams (1 carton) 5,000 sheets 10% Savings + Free Shipping

More About This Product

About this Product

Product Uses

- Bulletins

- Direct Mail

- Envelope Stuffers

- Flyers

- Posters

Specs

| Mill | Mohawk Fine Papers |

|---|---|

| Brand | BriteHue |

| Product Type | Paper |

| Size | 8 1/2 x 11 |

| Printer Compatibility | Copiers (B&W) Copiers (Color) DI Printers Digital Press Inkjet Printers Laser Printers Offset Printing |

| Finish | Semi-Vellum |

| Coating | Uncoated |

| Grain Direction | Grain Long |

| Recycled Percentage | 30 |

| Eco Features |

Green Seal Certified

Made Using Wind Power

Processed Chlorine Free

Recycled Content

|

| Paper Weight |

60 lb Text

89 G/M2

Caliper 4.9

408 PPI

|

| Paperator™ Color Value |

CMYK

C = 25.39, M = 39.24, Y = 0, K = 25.69

RGB

R = 141.39, G = 115.14, B = 189.5

|

Printing Hints

Mohawk BriteHue

BriteHue Fluorescent Papers are easy to print on when following these simple hints. It is recommended to pre-test all printing procedures prior to press time to ensure the desired results are achieved.

OFFSET INKS:

Print BriteHue like any conventional uncoated paper. We recommend heat resistant, wax free in if you plan to follow lithography with xerographic or laser printing technologies.

HANDLING:

Keep BriteHue products wrapped until the moment of printing. It is essential to let the paper acclimatize, for a minimum of 24 hours – longer during cold weather – in the press room while still wrapped in mill packaging. Keep Brite- Hue products covered during drying, between passes and prior to any finishing work. Pressroom conditions should be as close as possible to 70 degrees, and 40-50% relative humidity.

VARNISH:

Varnish or aqueous coating is optional as a surface protector or to achieve varnish effects. Pre-test all varnishes or coatings for compatibility.

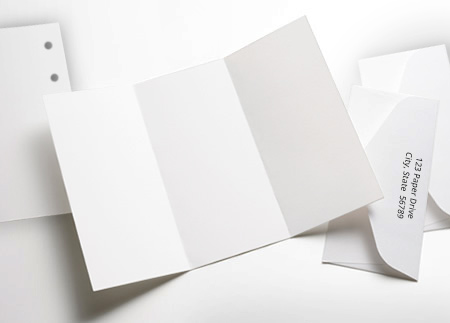

FOLDING AND SCORING:

For best results, 100lb. text papers and all cover weights should be scored before folded. Folds against the grain, gatefolds, and folds running throughout heavily inked areas should also be scored. As a general rule of thumb, the correct creasing channel is determined by multiplying the paper’s caliper by two and then add the width of the creasing rule. (Note each 1 pt. of rule equals .014 inch). Mohawk recommends a minimum 2 pt. rule for all scores both with and against the grain. Sometimes a wider score must be added – but too much width can be worse than too little, causing the sheet to fold unevenly on one side of the score rather than the center. A double, parallel score can be used to keep it straight.

BINDING:

BriteHue is suitable for all standard binding processes. It is important to plan for proper grain direction in all binding applications. Grain direction should run parallel to the spine for optimum results.

FOIL STAMPING:

It is recommended to pretest foils to find the best release, time and temperature for the size of the foil stamp and color of foil for each specific job.

LASER GUARANTEED

on all BriteHue items, subject to printer restrictions.

Paper Services

Choose from services including perforating, cutting, hole punching and scoring

Learn More