Elan Metallics Champagne Card Stock - 8 1/2 x 11 in 107 lb Cover Metallic C/2S 25 per Package

by WorldWin Paper

see more detailsAdd Paper Services

Paper services are available when viewing this page on a desktop computer

Select Paper Services

Matching Products

-

Elan Metallics Champagne Paper - 8 1/2 x 11 in 80 lb Text Metallic C/2S 250 per Package

-

Elan Metallics Champagne Paper - 8 1/2 x 11 in 80 lb Text Metallic C/2S 25 per Package

-

Elan Metallics Champagne Paper - 12 x 12 in 80 lb Text Metallic C/2S 25 per Package

-

Elan Metallics Champagne Paper - 12 x 12 in 80 lb Text Metallic C/2S 250 per Package

- See all color matched products

-

Elan Metallics Champagne Paper - 8 1/2 x 11 in 80 lb Text Metallic C/2S 250 per Package

-

Elan Metallics Champagne Paper - 8 1/2 x 11 in 80 lb Text Metallic C/2S 25 per Package

-

Elan Metallics Champagne Paper - 12 x 12 in 80 lb Text Metallic C/2S 25 per Package

-

Elan Metallics Champagne Paper - 12 x 12 in 80 lb Text Metallic C/2S 250 per Package

More About This Product

About this Product

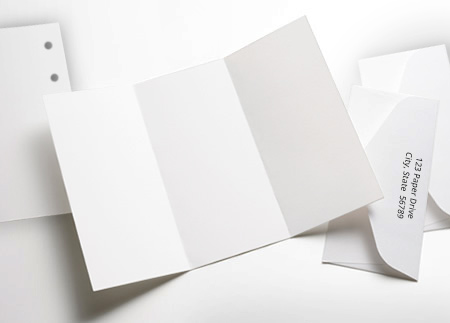

Product Uses

- Announcements

- Birth Announcements

- Booklets

- Brochure Covers

- Business Cards

- Card Making

- Covers

- Embellishments

- Greeting Cards

- Hang Tags

- Invitations

- Menus

- Packaging

- Place Setting Cards

- Scrapbooking

- Wedding Place Cards

Specs

| Mill | WorldWin Paper |

|---|---|

| Brand | Elan Metallics |

| Product Type | Card Stock |

| Size | 8 1/2 x 11 |

| Printer Compatibility | Offset Printing |

| Finish | Metallic |

| Coating | C/2S |

| Grain Direction | Grain Long |

| Paper Style | Metallic Super Heavy |

| Eco Features |

Lignin Free

|

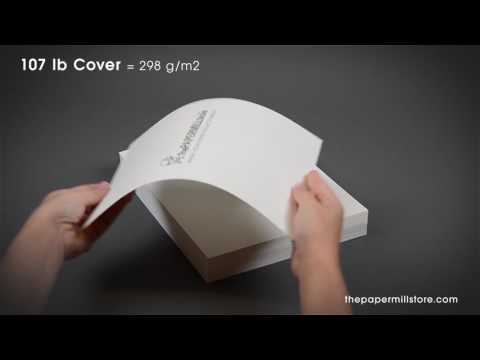

| Paper Weight |

107 lb Cover

290 G/M2

Caliper

PPI

|

| Paperator™ Color Value |

CMYK

C = 19, M = 1, Y = 7, K = 3

RGB

R = 223, G = 224, B = 196

|

Printing Hints

Elan Metallics®

Elan Metallics® Colored Papers are easy to print on when following these simple hints. We recommend you pre-test all procedures prior to press time to ensure you achieve the desired results.

INKS:

Elan Metallics have a partially absorbent to non-absorbent surface. For optimum results, we recommend inks that dry by oxidation and are 100% VOC free. Please consult your ink manufacturer prior to printing. Some offsetting of the pigment particles to the blanket may occur during printing but should not affect the image quality and will not require special wash-ups.

HANDLING:

Keep Elan Metallics wrapped in mill packaging until the moment of printing. It is essential to let the paper acclimatize in the press room for a minimum of 24 hours – longer during cold weather. Also keep Elan Metallics covered during drying, between passes and prior to any finishing work. Pressroom conditions should be as close as possible to 68 degrees and 45-60% relative humidity. If the bindery has a different climate than the pressroom, allow the paper to acclimatize to those conditions.

REVERSE:

Elan Metallics are equally coated on each side. We recommended you print both sides of the first 20 sheets of each carton to ensure you achieve the desired results on each side.

DELIVERY:

For optimum results, set jogger pressure to a minimum and lifts at 3 to 5 inches.

COATING:

Low solvent (0-5%) varnish or aqueous coating is optional as a surface protector or to achieve design effects. Pre-test all coatings for compatibility.

FOUNTAIN SOLUTION:

Run water at minimum levels with a minimum pH of 4.0. Solid or multiple color bars can be used to assist in removing water and aid in ink set time.

CUTTING:

Use care when cutting Elan Metallics. Use a sharp knife with minimum clamp pressure. To achieve a clean edge, back trimming is essential. Wipe the newly cut edge with a clean, soft, glycerin-saturated cloth.

FOLDING AND SCORING:

To properly score Elan Metallics, start with a 2 point rounded channel score. The matrix channel should be a minimum width of 2.5 times the caliper of the sheet to be scored, plus 0.028” - normally 0.050” for text and 0.060” for cover.

BINDING:

Elan Metallics are suitable for all standard binding processes. It is important to plan for proper grain direction in all binding applications. Grain direction should run parallel to the spine for optimum results.

FOIL STAMPING:

For optimum results, use foils suitable for plastic materials.

Paper Services

Choose from services including perforating, cutting, hole punching and scoring

Learn More