Glama Natural Clear Paper - 23 x 35 in 40 lb Bond Translucent Vellum 125 per Package

by CTI Paper USA

see more detailsBuy in Bulk and Save

- 6 Packages (1 carton) 750 sheets 10% Savings + Free Shipping

Matching Products

-

Glama Natural Clear Envelopes - A2 (4 3/8 x 5 3/4) 29 lb Bond Translucent Vellum 250 per Box

-

Glama Natural Clear Envelopes - A6 (4 3/4 x 6 1/2) 29 lb Bond Translucent Vellum 250 per Box

-

Glama Natural Clear Envelopes - A7 (5 1/4 x 7 1/4) 29 lb Bond Translucent Vellum 250 per Box

- See all color matched products

More About This Product

About this Product

Product Uses

- Announcements

- Annual Reports

- Belly Bands

- Brochures

- Bulletins

- Card Making

- Catalogs

- Corporate Identity Communications

- Direct Mail

- Fly Sheets

- Flyers

- Greeting Cards

- Holiday Cards

- Invitations

- Marketing Campaigns

- Outer Wraps

- Overlays

- Promotional Inserts

- Sell Sheets

Specs

| Mill | CTI Paper USA |

|---|---|

| Brand | Glama Natural |

| Product Type | Paper |

| Size | 23 x 35 |

| Printer Compatibility | Copiers (B&W) Copiers (Color) Laser Printers Offset Printing |

| Finish | Translucent Vellum |

| Coating | Uncoated |

| Grain Direction | Grain Long |

| Paper Style | Folio Translucent |

| Eco Features |

Elemental Chlorine Free

FSC Certified

Lignin Free

|

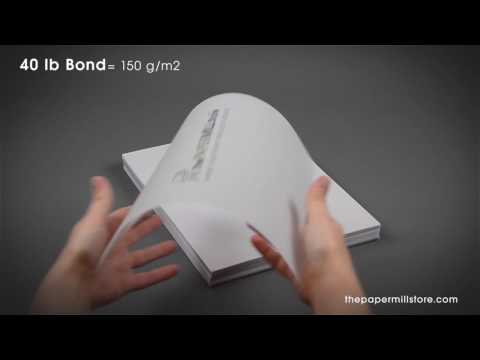

| Paper Weight |

40 lb Bond

150 G/M2

Caliper 4.7

425 PPI

|

| Brightness | 56 |

| Paperator™ Color Value |

CMYK

C = 28, M = 2, Y = 8, K = 5

RGB

R = 130, G = 130, B = 130

|

Printing Hints

Glama Natural®

Glama Natural® Translucent Printing Papers are easy to print on when following these simple hints. We recommend you pre-test all procedures prior to press time to ensure you achieve the desired results.

INKS:

For optimum results, we recommend low-solvent (0-5%), oil-based inks that dry by oxidation. Ink with higher than recommended solvent content may cause ink-set difficulties. In-plant ink formulation is not recommended. Normal heatset and UV inks have printed successfully on Glama Natural and eliminate drying time. Ask your ink manufacturer about Glama Natural products specifically.

HANDLING:

Keep Glama Natural wrapped in mill packaging until the moment of printing. It is essential to let the paper acclimatize in the press room for a minimum of 24 hours – longer during cold weather. Also keep Glama Natural covered during drying, between passes and prior to any finishing work. Pressroom conditions should be as close as possible to 68 degrees and 45-60% relative humidity. If the bindery has a different climate than the pressroom, allow the paper to acclimatize to those conditions. Should you experience a curl problem it is most likely temperature – or humidity – related. We recommend printing in small lifts and frequent airing of lifts. Avoid using on-press heat and drying systems.

FOUNTAIN SOLUTION:

Run the ink-water balance at an absolute minimum. The pH should not be below 4.0. We suggest adding up to 10% alcohol. Given the non-porous property of Glama Natural, excess water won’t be absorbed or removed from the blanket. Any excess water will slow drying time. Solid or multiple color bars can be used to assist in removing water and aid in ink set time.

OFFSET SPRAY:

If the job requires offset spray, use coated spray of normal fineness.

VARNISH:

A clear, overprint varnish can be used to seal the sheet and reduce curling when Glama Natural is used as a cover, wrap, free-hanging application or when very heavy ink coverage is applied to one side of the paper. Apply 100% VOC-free varnish after the underlying ink is dry. Consult your varnish supplier and pre-test for compatibility. Do not use aqueous coatings.

CUTTING:

Do not use a newly sharpened blade when cutting Glama Natural products as it may chip. A slightly dull but clean-edged blade with a 23º-bevel angle is ideal.

FOLDING AND SCORING:

Always fold, score and bind with the grain direction. Start with a 2 point rounded channel score. The matrix channel should be a minimum width of 2.5 times the caliper of the sheet, plus 0.028”, usually 0.040” or 0.050”. Do not use sharp tools when folding and scoring.

Paper Services

Choose from services including perforating, cutting, hole punching and scoring

Learn More